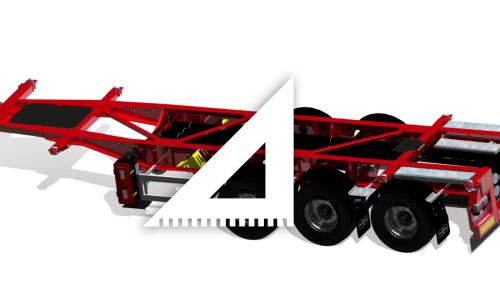

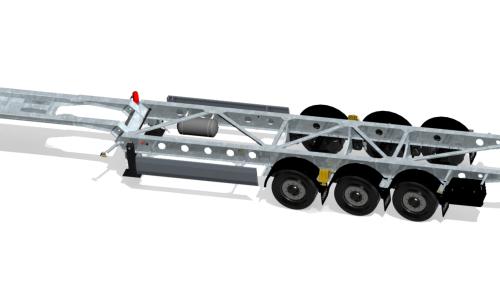

Container chassis

For years now, Van Hool has been building a very wide range of container chassis for the transportation of standard containers, tank and bulk containers and swap tanks. They are made of high grade steel and are available in 20´, 30´, 40´ and even 45´ versions. As standard, most of our container chassis are also painted using our top-quality Van Hool zinc-rich painting process, with more than 85% zinc in the primer. For certain types we also offer the possibility of galvanising the chassis.

The lowest possible tare weight is of fundamental importance for the container chassis. Without making any compromises on our renowned reliability, Van Hool combines ultra-competitive empty weights with robustness.